After the appearance design of mechanical equipment products, most of them will use sheet metal processing, which is determined by the characteristics of the industry. Designers who are engaged in the ID design of industrial equipment are very confused about the use of materials, and they are also confused about what teachers teach at school. From the perspective of the industry, the application environment of the machine is relatively harsh, the strength of the plastic material is not enough, it is easy to break, and the strength and toughness of the metal parts can be satisfied

Request; From the perspective of technology, plastic parts need to open the mold, the cycle is long, at least more than 30 days, the cycle of large parts may reach 45 days, or even more than 60 days, and the sheet metal parts are generally about 7 days; From the perspective of cost, the plastic mold movement of large pieces is hundreds of thousands, but the sheet metal parts may only need a few thousand yuan; From the point of view of batches, there is no amount of formation

Although the cost of a single piece of sheet metal parts will be higher than that of plastic parts, there is no need to share the mold cost.

Sheet metal processing is a comprehensive cold working process, including shearing, punching/cutting/compounding, folding, welding, riveting, splicing, forming (such as automobile body), etc. Its distinctive feature is that the thickness of the same part is the same.

Sheet metal processing is called sheet metal processing. For example, the use of plates to make chimneys, iron drums, oil tanks, ventilation pipes, elbow heads, Tianyuan places, funnel shapes, etc., the main processes are shearing, bending buckles, bending forming, welding, riveting, etc., which require certain geometric knowledge.

Sheet metal parts are thin plate hardware, that is, parts that can be processed by stamping, bending, stretching and other means, a general definition is-

Parts with constant thickness during machining. The corresponding parts are castings, forgings, machining parts, etc., for example, the iron shell on the outside of the car is sheet metal parts, and some cabinets made of stainless steel are also sheet metal parts.

1. It is a processing method for automobile maintenance, also known as cold work.

To put it bluntly, if the appearance of the body is damaged and deformed, the process of sheet metal is needed to restore the original appearance.

Basically, the tool used is a hammer. Hammers of different shapes, horn blocks behind the sheet parts, repeatedly struck to make them shape.

Cosmetic restorers are also used when necessary. This thing actually belongs to welding. Weld the iron girth to the body and pull it out with a hook. It is used to repair sunken areas.

It is generally difficult to get back into place with a large flat body, so sometimes it is necessary to close the fire. It is to cool after local heating, so that the iron sheet shrinks.

The ultimate goal is to restore the damaged body to its original appearance.

2. Sheet metal: Sheet, that is, the meaning of plate, thin plate, is the meaning of a series of processing of thin metal plates, including folding, shearing, punching, welding, riveting, splicing and other processes

3. This is a design module, mainly for things made with iron sheet materials. He is different from the entity, the thickness of the entity changes, but the sheet metal is basically the same thickness, and there are many products made of sheet metal in life.

Mechanical appearance design needs to be combined with processing technology to make good products. Earlier we said that the sheet metal process includes shearing, punching/cutting/compounding, folding, riveting, splicing, forming, etc., what kind of design conforms to the shearing and punching of sheet metal, you need to go to the sheet metal factory to learn on the spot, including how the sheet metal factory disassembles parts, how to do unfolding.

For equipment design, the issue that ID design companies also need to consider is the control of costs. Industrial design is not artistic creation, industrial design is first of all technology, is the application, to make Party A's products can make money, so cost control is another key to landing. Good equipment industrial design products must withstand the criticism and scrutiny of the sheet metal processing factory, from color matching to knotting

structure, from the thickness of the plate to the disassembly. Of course, when landing, you also have to find a good sheet metal factory, although some sheet metal factories do equipment sheet metal all year round, but in fact only have processing capacity, still rely on the original master master model, no sheet metal design ability. Sheet metal design refers to the later disassembly and unfolding of parts by a special engineer to do it, which will form a complete drawing.

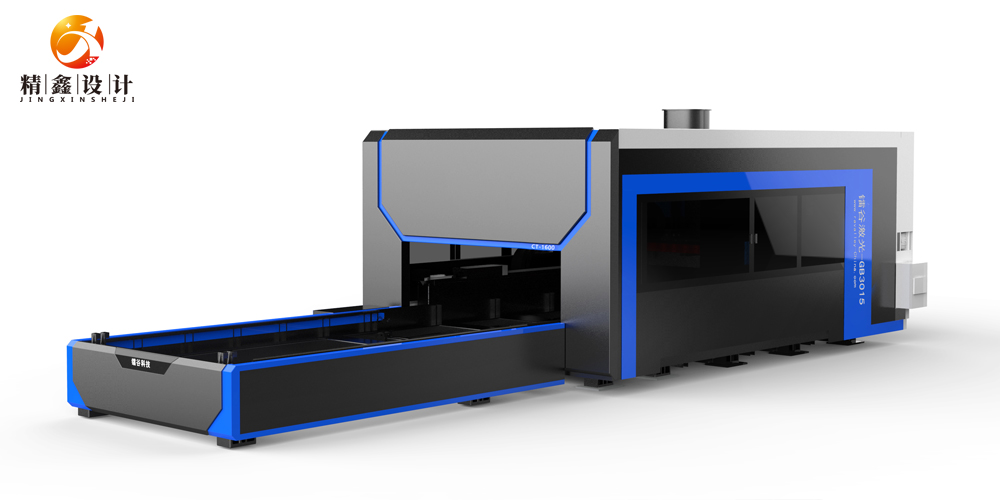

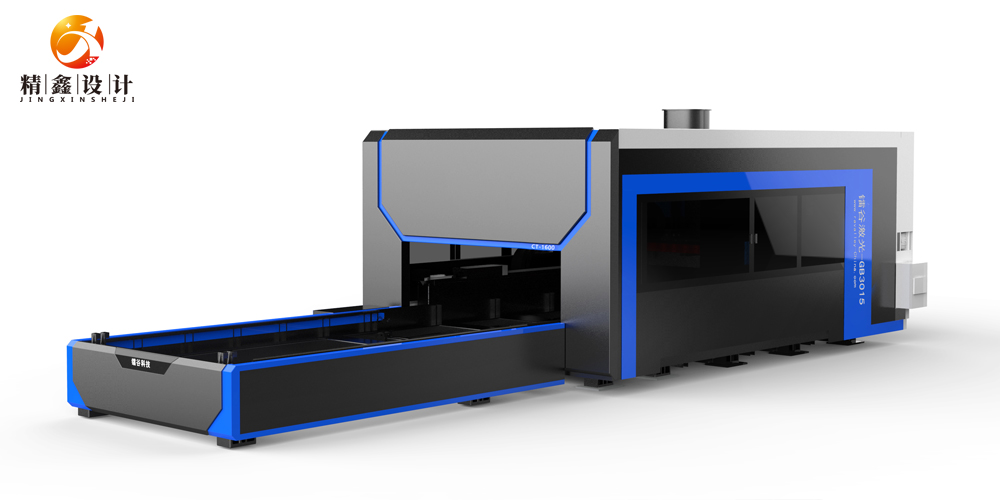

Machinery and equipment design, Jingxin Industrial Design Company has considerable experience. As a senior design expert of industrial equipment, product design is important, but to truly reflect the characteristics of industrial equipment design, it must rely on sheet metal technology.

Precision Design

Precision Design with us:15302653652

with us:15302653652